Manufacturing Processes &

Production Capacity

BUSINESS DEPARTMENT

Built on our melting and die-casting capabilities, we develop and produce core automotive components.

Process Flow

-

1 Melting

- Melting

- Raw aluminum ingots are melted in a high-temperature furnace, impurities are removed, and the molten metal is then fed into the casting process.

-

2 Casting

- Casting

- Molten metal is injected into a die-casting mold to form components in the desired shape. Using high pressure to force the metal into the mold, die casting enables the production of highly precise parts with smooth, high-quality surfaces.

-

3 Deburring

- Deburring

- This process removes surface imperfections and unwanted protrusions (burrs) from cast parts produced in the die-casting process. By removing burrs, we enhance product quality, improve safety, and deliver a cleaner overall appearance.

-

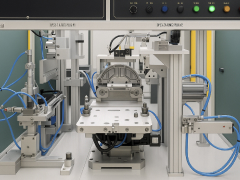

4 Machining

- Machining

- Cast parts are precisely machined to meet design specifications. Using automated machining equipment, we secure tight dimensional accuracy, finish critical surfaces, and process features such as holes and other detailed geometries.

-

5 Assembly

- Assembly

- Machined parts are assembled into the final product. At this stage, we verify functionality, durability, and overall reliability through thorough quality testing.

Detailed production line processes

-

Automated sub-material assembly

-

Robotic operation of casting processes

-

Robotic operation of machining processes

-

Mold storage

-

Robotic deburring

-

Heat-treatment furnaces

-

Packaging and shipment

-

X-SCADA

| 적용부 | Product Name | Annual Production Volume | Key Customers | Production Facilities (Casting) |

|---|---|---|---|---|

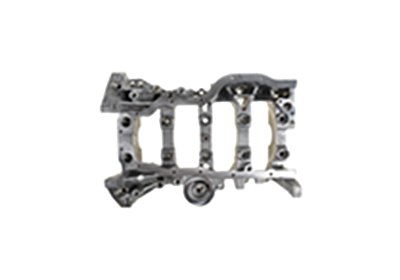

| Engine Part |

Lower Crankcase |

2.6 million units | Hyundai Moter Company / GM |

1,400T 2,250T |

Timing Chain Cover |

1.5 million units | Hyundai Moter Company / GM |

850T 1,250T |

|

Oil Pan |

0.3 million units | Hyundai Moter Company / GM |

850T |

|

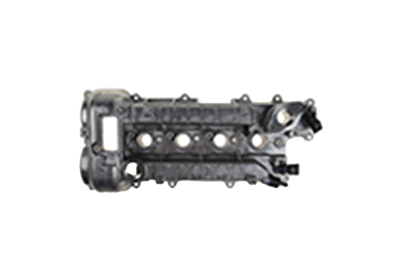

Cylinder Head Cover |

0.4 million units | Hyundai Moter Company |

850T |

|

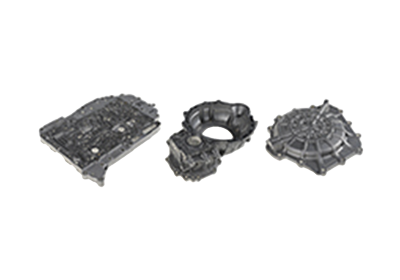

| Transmission Parts |

Transmission Parts |

0.7 million units | Hyundai Powertech |

850T |

| Hybrid |

Hybrid Components |

300,000 sets | Hyundai Mobis |

850T 1,250T |

Equipment Status

| Category | Category | Equipment Name | Quantity/CAPA | Notes | |

|---|---|---|---|---|---|

| Casting | High-Pressure Die-Casting Machine | 2,250T | 2uints | 17units (6,000,000 shots / Year) |

▶ UZ-Auto IZNI Plant 1,650 T / 2 units 1,250 T / 1 unit 350T / 5 units |

| 1,650T | 2uints | ||||

| 1,400T (* Magnesium Casting Capable) | 4uints | ||||

| 1,250T | 5uints | ||||

| 850T (* Magnesium Casting Capable) | 4uints | ||||

| Melting Furnace | High-Speed Melting Furnace | 4uints | 95,000T Melting / Year | ||

| Machining | Machining & Assembly | Tapping center | + 1,200 units |

Crank Case Equipment Automated Production Line Established |

|

| Machining center | |||||

| CNC Lathe | |||||

| Assembly M/C | |||||

Simulation

To maintain the highest product quality, we have established a pre-validation system through casting simulation, supported by specialized analysis engineers.

-

1Casting Simulation for Products

-

2Predicting moldability and internal defects in the casting process

-

3Defining optimal casting and process parameters

-

4Ensuring the highest product quality in the industry

-

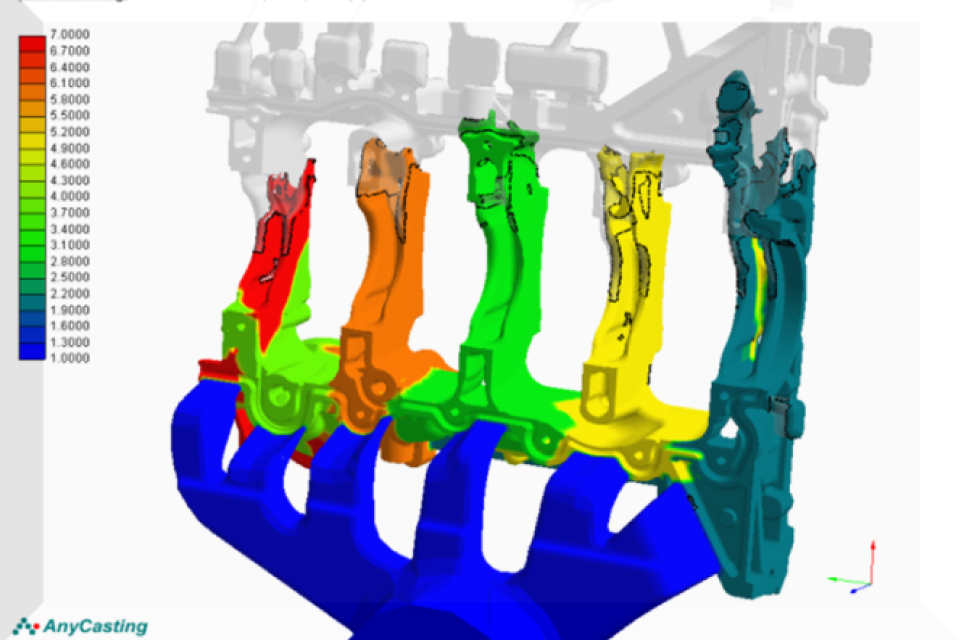

Molten Metal Flow Analysis (Flow behavior analysis using gate-based color visualization)

-

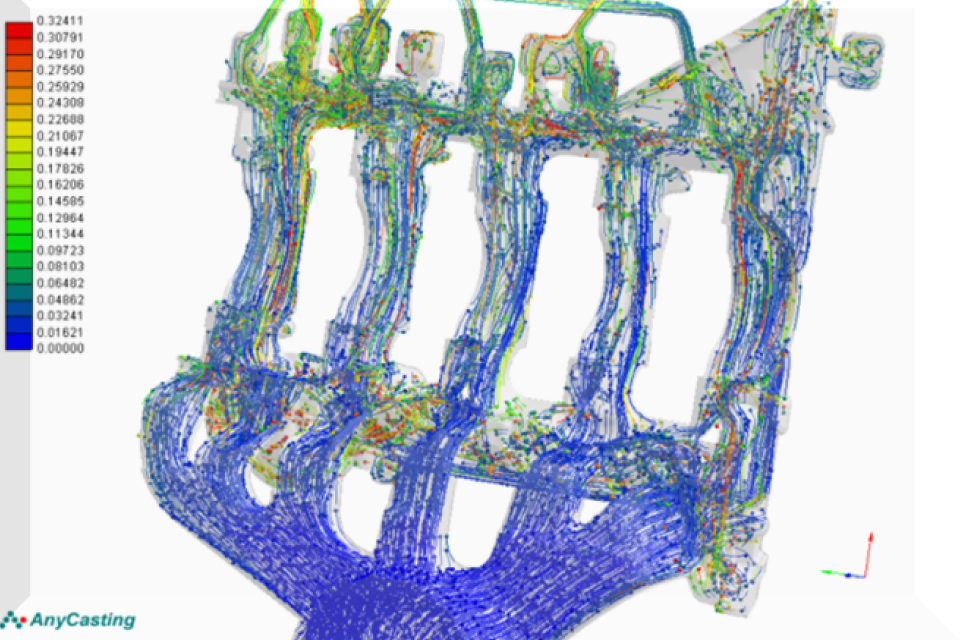

Filling Analysis (Turbulence analysis during mold filling)

-

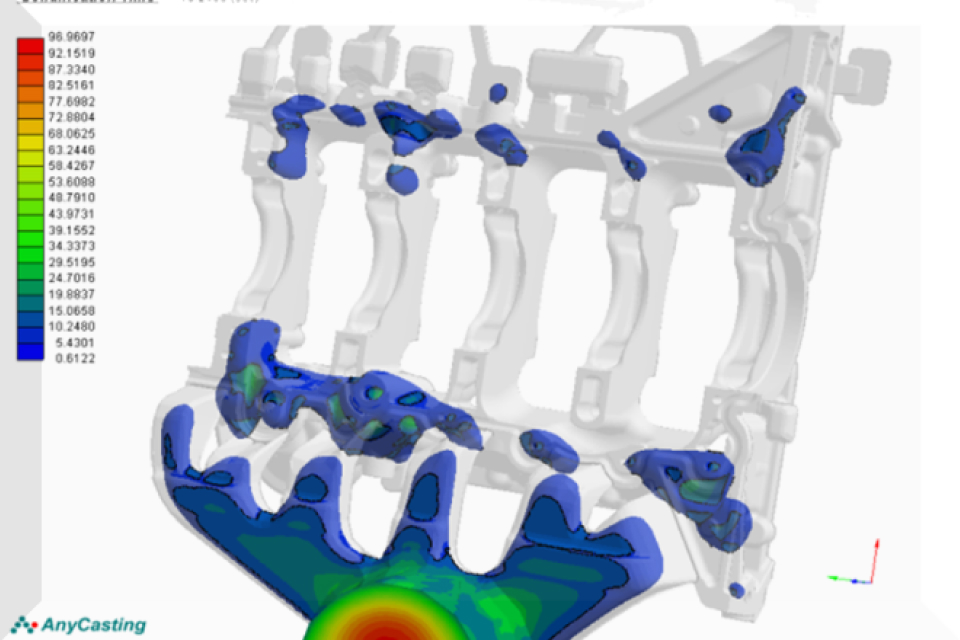

Solidification Pattern Analysis (Prediction of solidification behavior and major solidification defects)

Research & Development

(New Materials & New Processes for Lightweighting)

| Items | Details |

|---|---|

| Pipe Insert Die Casting | Pipe insert application |

| Forged-Aluminum Insert Die Casting | Cast iron → Forged aluminum insert (30% weight reduction) |

| Crank Case without Insert | Removal of cast-iron bearing caps → aluminum structure without Insert |

| Ultra-Lightweight Magnesium Die Casting | Aluminum → Magnesium die casting, 30% lighter (Applicable to oil pans, transmission housings, etc.) |

| Metal 3D Printing | New metal 3D printing technology (Chungnam Industry-Academia Research) |

Quality Measurement Equipment

-

Profile projector

-

Micro hardness tester

-

Chemical spectrometer

-

Microscope

-

Surface Roughness Tester

-

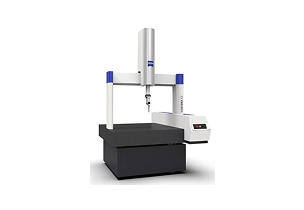

3D inspection Equipment

-

CT X-ray Equipment

-

Contracer

-

Hardness tester